what is aluminum profile

For the beginning of this article, we need to know what exactly aluminum profile is and how is it being manufactured.

Aluminum profiles are shape of linear aluminum products that have the form by pushing heated aluminum billets through a shaped-opening in a die.

Because of this it is possible to manufacture different shapes of aluminum profiles.

People use Aluminum profiles all around the world in various industries, for instance construction, automotive, electronics, and more.

They have valuable advantages over other materials, such as their lightweight nature, corrosion resistance, high strength-to-weight ratio, and excellent thermal conductivity. For the next step we take a closer look at different types of aluminum profiles using in industries and constructions.

Extruded Aluminum Profiles

Most common type of aluminum profiles are extruded aluminum profiles.

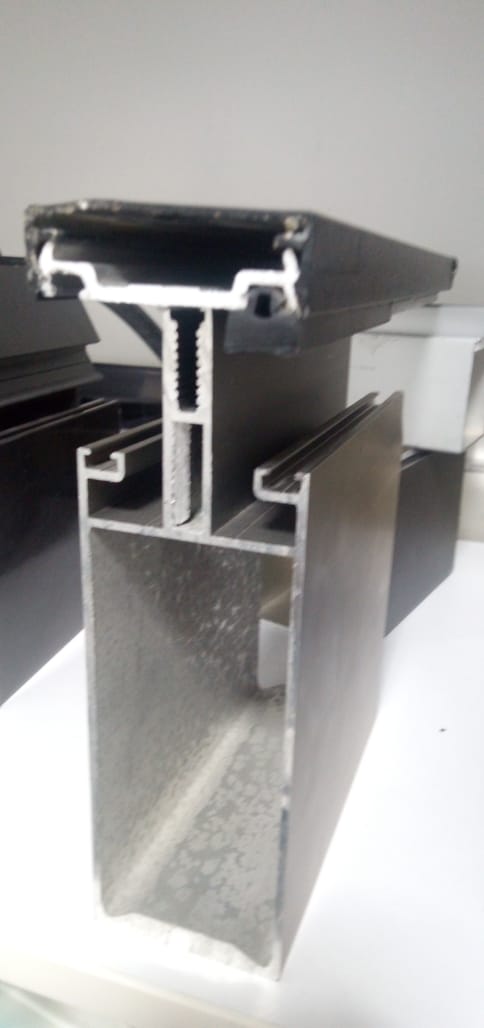

Extruded aluminum profiles are linear-shaped aluminum products that are created through the process of aluminum extrusion.

This manufacturing process involves pushing or extruding heated aluminum billets through a shaped opening in a die, resulting in the formation of long continuous profiles with consistent cross-sectional shapes.

The beginning of the extrusion process is with the selection of an aluminum alloy in the form of billets or logs,

We heat These billets to a specific temperature and then push them through a steel die using a hydraulic press.

The die determines the shape and dimensions of the extruded profile. The extruded aluminum emerges from the die in a continuous length and is then cooled, straightened, and cut to the desired lengths.

Extruded aluminum profiles offer several advantages:

1. Design flexibility:

Aluminum extrusion allow the creation of complex cross-sectional shapes that are customizable to meet specific design requirements, The profiles can have various geometries, such as T-shapes, I-beams, angles, channels, and more.

2. Lightweight and high strength:

Aluminum is inherently lightweight, making extruded aluminum profiles suitable for applications where weight reduction is important, Despite their low weight, these profiles offer high strength and structural integrity.

3. Corrosion resistance:

Aluminum naturally forms a protective oxide layer on its surface, providing inherent resistance to corrosion,

Additionally, extruded aluminum profiles can be further enhanced with surface treatments,

such as anodizing or powder coating, to increase their corrosion resistance.

4. Thermal conductivity:

Aluminum is an excellent conductor of heat, making extruded aluminum profiles ideal for applications requiring efficient heat dissipation or thermal management.

5. Cost-effective production:

Aluminum extrusion is a highly efficient and cost-effective manufacturing process. It allows for the production of complex profiles in large quantities with consistent quality, reducing production costs compared to other fabrication methods, Extruded aluminum profiles find applications in various industries, including construction, automotive, aerospace, electronics, machinery, and consumer goods. People use them for structural frameworks, window and door frames, heat sinks, enclosures, support structures, and many other applications where lightweight, strong, and customizable profiles .

Anodized Aluminum Profiles

Anodized aluminum refers to the process of creating an oxide layer on the surface of aluminum through an electrochemical process called anodization, This process enhances the natural oxide layer that forms on aluminum when exposed to air, creating a more durable and corrosion-resistant finish.

During anodization, the aluminum profile is immersed in an electrolytic bath and serves as the anode (positive electrode), A direct current is passed through the electrolyte,

causing oxygen ions to combine with the aluminum atoms on the surface, forming aluminum oxide.

This oxide layer is integral to the metal and provides increased hardness and protection.

The anodization process is customizable to achieve different thicknesses of the oxide layer, resulting in various levels of durability, appearance, and color options.

The thickness of the anodized layer can range from a few microns to several tens of microns.

The benefits of anodized aluminum profiles include:

1. Corrosion resistance:

The anodized layer acts as a barrier, protecting the underlying aluminum from environmental factors, such as moisture, chemicals, and UV radiation.

2. Durability:

Anodized aluminum is harder and more scratch-resistant than raw aluminum, It can withstand wear and tear,

making it suitable for applications where the material may come into contact with abrasive substances or frequent handling.

3. Aesthetic appeal:

Anodized aluminum can be produced in various colors,

including black, bronze, gold, and silver,

The process does not involve the application of a coating but rather modifies the surface of the aluminum,

resulting in a long-lasting color finish.

4. Thermal insulation:

Anodized aluminum has better thermal insulation properties compared to other metals, making it suitable for applications requiring heat dissipation or insulation.

Die-Cast Aluminum Profiles Die-cast aluminum profiles are not a commonly used term,

Die-casting is a manufacturing process where molten metal,

such as aluminum, is injected into a steel mold, or die,under high pressure.

This process is typically used for producing complex-shaped parts with high dimensional accuracy,

People commonly apply Die-casting to produce individual components rather than continuous profiles.

The process involves the following steps:

1. Mold Preparation:

The steel mold, or die, is prepared by creating two halves with a cavity in the desired shape of the part to be produced. The mold is then securely clamped together.

2. Injection:

Molten aluminum is injected into the die cavity under high pressure using a specialized machine. The pressure helps to fill the mold completely and ensures that the part takes on the shape of the cavity.

3. Cooling and Solidification:

After we inject the liquid aluminum into the mold, it the temperature will rapidly drop and it will become solid within the die. We carefully control the cooling time to ensure proper solidification and dimensional stability.

4. Ejection:

Once the part has become solid, the mold is open, and we eject the part from the die cavity using ejector pins or other mechanisms.

Die-casting offers several advantages for aluminum parts production, including:

1. Complex Shapes:

The process allows for the production of intricate and complex-shaped parts with high precision and fine details.

2. High Production Rates:

Die-casting is a high-speed production method, enabling the rapid production of large quantities of parts.

3. Good Surface Finish:

Die-cast aluminum parts typically have a smooth and uniform surface finish, requiring little to no additional finishing processes.

4. Excellent Strength:

Die-cast aluminum parts exhibit high strength and rigidity, making them suitable for applications that require structural integrity.

We commonly use die-casting in the automotive, aerospace, electronics,

and consumer goods industries to produce various aluminum components, such as engine parts, housings, brackets, and other intricate parts.

However, it is not typically associated with the production of continuous profiles like extrusion.

Overall, aluminum profiles are durable, and lightweight solutions that offer dignificant design flexibility and functional and huge performance benefits across various applications.

our offers

Types and examples of curtain wall construction and execution Building Facade|facade engineering|facade materials Ceramics Facades|Handrails|Terracotta Facade|Thermowood WPC Wood Plastic|facades glass|dryfacade (Aluminum Louvers)

Detailed technical and executive information for those interested Also, Here are some of the capabilities of this company:

aluminum company producer factory in Manufacture aluminum

such as profile windows & door aluminum

Details of the Valid Aluminium Company of factory products

Curtain Walls|Frameless glass facade|Aluminum louver

Skylight glass|Dry ceramic|Dry stone|aluminum profile