aluminum profile manufacturing extraction process

Aluminum is one of the most valuable elements that humans can find in nature,

which we are using widely in industry.

In this article, we want to review the steps of aluminum production in a nutshell to know how this precious metal is prepared for use in buildings.

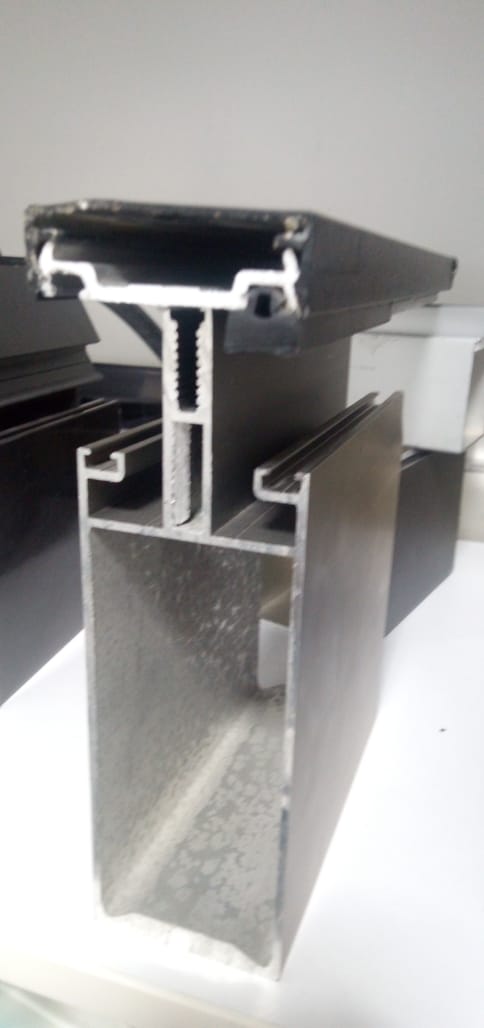

Extrusion process for aluminum production

First step: Preparing the prerequisites

We need an extrusion mold to produce aluminum profiles,

which is usually of steel, Since extrusion is a thermal process,

you must heat the mold to about 400 or 500 degrees Celsius before injecting the aluminum material.

Second step: preparing the aluminum rod.

We extrude Aluminum into a long, cylindrical rod with a small diameter.

Before extrusion, we heat this bar to some extent so that its temperature is close to the temperature of the press chamber.

In this case, aluminum is not molten but malleable.

Third step: Aluminum enters the press.

when the aluminum reach the desired temperature, it is placed on the roller rails to enter the press chamber.

The important point in this part is that aluminum is coated with an oily substance so that it does not stick to the body of the extrusion section if it is too hot.

Fourth step: the effect of pressure on aluminum

In this step, we completely place the hot aluminum rod inside a cylinder and a very strong piston puts pressure on it.

The piston can apply a huge hydraulic pressure of up to 15000 tons on the material so that it comes out of its rod form and turns into an extrusion chamber.

In fact, the chamber has exactly the same section form that the industrial unit needs to produce, Aluminum profiles are produced with various sections and you can refer to Valid company’s website.

This industrial group is selling aluminum profile online and has everything you might need in its online store.

Fifth Step: The aluminum material comes out of the section.

As we said, aluminum materials fill the entire chamber and finally form the section you need, What gives shape to aluminum is the exit opening, which is designed exactly according to the required standards.

When the pressure of the piston enters, the aluminum comes out of the outlet and takes the shape of the same section because it is heated.

Aluminum production with different sections

The sixth step: cooling the aluminum profile

Now that the aluminum has been removed from the cylinder, it must be cooled.

There are two ways to do this, one is cooling with water and the other is cooling by air flow. Each factory can perform one of these methods according to its own conditions and with the opinion of metallurgical engineers.

Seventh step: cutting the new aluminum profile

Now that the new profile is out of extrusion and in the process of cooling, it is cut into the required lengths with a hot steel saw.

Where to get the best aluminum profiles?

You can contact valid Industrial Group to buy the best aluminum profiles and even curtain walls.

our offers

Types and examples of curtain wall construction and execution Building Facade|facade engineering|facade materials Ceramics Facades|Handrails|Terracotta Facade|Thermowood WPC Wood Plastic|facades glass|dryfacade (Aluminum Louvers)

Detailed technical and executive information for those interested Also, Here are some of the capabilities of this company:

aluminum company producer factory in Manufacture aluminum

such as profile windows & door aluminum

Details of the Valid Aluminium Company of factory products

Curtain Walls|Frameless glass facade|Aluminum louver

Skylight glass|Dry ceramic|Dry stone|aluminum profile